|

|

| We are created to do good. |

|

|

|

|

Easy and price affordable solution for your daily applications in workshop, laboratory and outdoors. Well balanced between ergonomics and functionality.

Easy and price affordable solution for your daily applications in workshop, laboratory and outdoors. Well balanced between ergonomics and functionality.

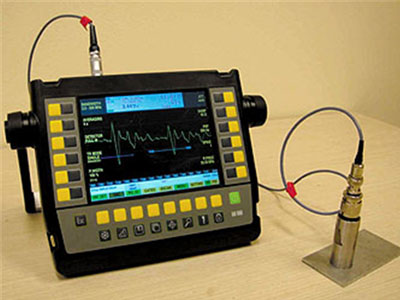

New generation of electronic components, fast micro-processors and our long-term experience in manufacturing of ultrasonic instruments enabled us to develop really advanced revolutionary ultrasonic flaw detector Defectobook�� DIO1000 with the best parameters and functions. |

| MAIN FEATURES: |

Well balanced between ergonomics and functionality: easy solutions for your daily applications in workshop, laboratory and outdoors. Due to its adjustable handle, the instrument sits stable on any surface you encounter, even on round parts.

Large bright color LCD screen 1024 x 768 pixels, excellent visibility on the direct sunlight.

Optimum performance and extended connectivity.

Lightweight 1,28 kg / 3,04 lbs and just 34 mm thin.

The DIO 1000 combines the powerful advantages of digital design with the detailed dynamic echo information to bring back the ��analog look and performance��, using sampling rate of 200 MHz.

Direct access to 12 main functions.

Burst pulser selectable and tunable for optimum probe matching to satisfy a wide range of tough-to-penetrate applications.

EMAT for non-contact testing.

Trigonometric flaw location function with curvature correction automatically calculate s depth, surface distance and sound path to flaw along with the leg of the inspection when using angle beam probes. All TOF measurements can be displayed in mm, inches or ��s.

Standard DAC, JIS-DAC, AVG, API, Automatic Thickness meter, Auto Gain, Auto Freeze, Automatic Calibration, Curved Surface Measurement.

Weld rating calculation simplifies the rating of indications in welds according to AWS Specification D1.1.

B-scan imaging - thickness mode or RGB palette.

|

|

|

- Tests for Damp heat / Humidity as per norms EN 600-2-78;02; EN 60068-1

- Vibration tests as per norm EN 60068-2-6 ed 2:08

- Shock tests as per norm EN 60068-2-29:1996+Z1:10

|

| 1) DIO 1000SFE with probe |

|

| 2) Spiraly welded tube OD40, 70, length 6000 |

|

| 3) Ultrasonic testing tube OD 75 |

|

| General specifications |

| Display Screen |

6“ TFT LCD, 1024x768 pixels

60Hzupdaterate |

| Display dimensions |

99x130mm |

| True sampling rate |

200MHz, 12-bit |

| Dimension (W x H x D) |

224 mm x 188 mm x 34 mm |

| Weight |

1.3 kg with battery |

| Battery |

Built-in Li-Ion battery 3.6V, 16Ah |

| Battery operating time |

Up to 10 hours |

| Languages |

Selectable, user-defined custom language |

| External Power Supply for Adaptor |

AC 80V~240V 50Hz/60Hz |

| Data Memory |

4 " 16GB (up to 40000 A-Scans) |

| Warranty: |

2 years, optional 3 years |

| Environment Tests |

| Operation Temperature |

-20��C~50��C |

| Storage Environment |

-40��C~70��C |

|

| Model type: |

DIO 1000 SFE |

| USB Connector |

One " Host USB |

| Encoder Connector |

A, B " pulses, TTL 5V, Start |

| Ethernet Connector |

External (optional on USB) |

| High Speed Parallel and TTL Port (optional) |

Alarm outputs, trigger in/out control |

| Analog Output |

Presence of echo in Gate, Thickness, Position of Echo flank in Gate, EchoStart + AUX |

| A/D Sampling Frequency |

200 MHz |

| Probe connector |

Mini Lemo�� |

| Scan Type |

B-scan Thickness / RGB amplitude |

| Focal Law quantity |

N/A |

| Scan Angle Range |

N/A |

| Scan Setup |

N/A |

| Range |

0~29000mm for PRF 100Hz, (Steel longitudinal wave) |

| Material Velocity |

1~19999 m/s |

| Display Delay |

-25~29000mm, (Steel longitudinal wave) |

| Auto Transducer Calibration |

Zero offset and velocity |

| Units |

mm, inch, ��s |

| Refracted Angle |

Fixed settings of 0��, 30��, 45��, 60��, 70��; variable 10��~90�� in 0.1�� steps for calculations |

| Test Modes: |

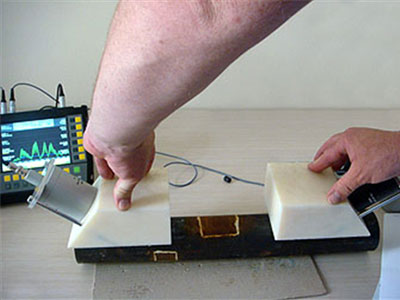

Pulse Echo, Dual, Through-Transmission, EMAT |

| Probe Delay Range |

-10��s~4800��s with 5ns resolution |

| Gate Monitors |

Four Gates: Floating gate, Interface gate, Measuring gate, Back-wall attenuator |

| Alarms |

Selectable threshold positive/negative or minimum depth modes |

| Cursors |

N/A |

| Display Mode |

A, B-Scan, TOFD |

| Auto Gate |

Thickness |

| TCG, DGS |

20 points |

| JIS, DAC |

20 points, plus 4 sub-curves |

| Spot weld (optional) |

Heuristic evaluation |

| Colour maps |

RGB |

| Test Point Selection |

Peak, Flank |

| Measurement method |

Four Gates: Each can measure echo amplitude, position, alarm

Gate1:SoundPath,Depth,SurfaceDistance(curvedsurface)

Gate2:Thickness

Gate3:Back-wallattenuator

Gate4:Interface

SkipdiagramforAngleprobes |

| Gate Start |

Full Range |

| Gate Width |

Full Range |

| Gate Trash |

2~98% |

| Pulser |

Unipolar Square Wave, Burst |

| Repetition Frequency |

10Hz~20kHz, peak envelope of A-scan display |

| Energy |

18~189V |

| Pulse Width |

15~5000ns |

| Damping |

50, 57, 180 and 1000�� |

| Pulser Focusing |

N/A |

| Pulser Delay |

N/A |

| Gain |

0~111dB with 0.1/0.5/1.0/6dB step |

| Digital Gain |

-6~36dB used for TCG |

| Bandwith |

0,5~30MHz at -3dB |

| Rectification |

Pos HW, Neg HW, FW and RF |

| Amplitude measurement |

0~150% FSH |

| Filter |

1,2, 2.25~2.5, 4, 5,10MHz BP; digital LP 6 to 50MHz |

| Reject |

0~70% |

| Receiver Delay |

N/A |

|

|

|

- Aerospace composite testing

- Steel production - large castings, hot and cold rolled steel

- Engineering - welds and joints

- Railway - track junctions in manganese steel

- Energy - austenitic welds, drive shafts etc.

- Pipe inspection

- Crack detection and sizing

|

|

|

|

|