|

|

| We are created to do good. |

|

|

|

|

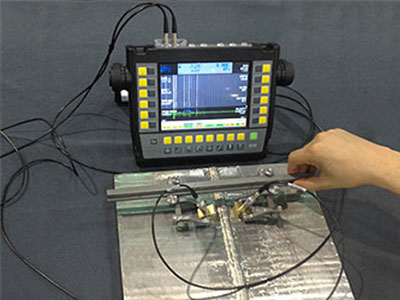

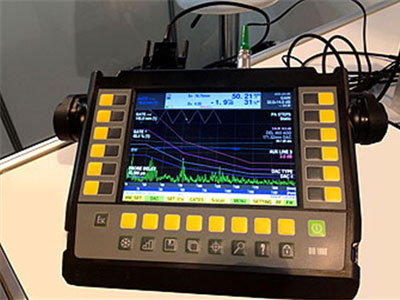

The new advanced DEFECTOBOOK�� DIO 1000 PA digital ultrasonic flaw detector is now augmented with phased array imaging capabilities. It is combining all features of conventional ultrasonic with power of phased array.

Using the latest generation of electronic components and microprocessors we have brought the thinnest, lightest and really portable phased array instrument, which makes your inspection easy and fast. The standard configuration is 16 parallel (in preparation 32 parallel), and with extendable module 16:64 and 16:128. The DEFECTOBOOK�� DIO 1000 PA complies with all common standards as EN12668-1, ASME Code case 2541, ASTM E2491, ASTM E2700. The instrument also combines the powerful advantages of digital design with the detailed dynamic echo information, using sampling rate 200 MHz, 12-bit. |

| Advantages of DIO 1000 PA |

- Thinnest phased array instrument

- Weight only 1.3 kg with battery

- Battery operating time up to 10 hours

- Lots of possibilities (A-SCAN, B-SCAN, C-SCAN, Weld manager, EMAT, Tofd,

|

| Environmental test |

- Tests for Damp heat / Humidity as per norms EN 600-2-78;02; EN 60068-1

- Vibration tests as per norm EN 60068-2-6 ed 2:08

- Shock tests as per norm EN 60068-2-29:1996+Z1:10

|

| 1) Weld manager |

|

| 2) PA with Tofd |

|

| 3) PA with Distance Amplitude Correction |

|

| 4) PA testing of composites |

|

| 5) PA testing of honeycomb |

|

|

|

|

| General specifications |

| Display Screen |

6“ TFT LCD, 1024x768 pixels

60 Hz update rate |

| Display dimensions |

99x130mm |

| True sampling rate |

200MHz, 12-bit |

| Dimension (W x H x D) |

224 mm x 188 mm x 34 mm |

| Weight |

1.3 kg with battery |

| Battery |

Built-in Li-Ion battery 3.6V, 16Ah |

| Battery operating time |

Up to 10 hours |

| Languages |

Selectable, user-defined custom language |

| External Power Supply for Adaptor |

AC 80V~240V 50Hz/60Hz |

| Data Memory |

4 " 16GB (up to 40000 A-Scans) |

| Warranty |

2 years, optional 3 years |

| Environment Tests |

| Operation Temperature |

-20��C~50��C |

| Storage Environment |

-40��C~70��C |

|

| |

Conventional Mode |

PA Mode |

| USB Connector |

One Host USB |

One Host USB |

| Encoder Connector |

A, B pulses, TTL 5V, Start |

A, B pulses, TTL 5V, Start |

| Ethernet Connector |

External (optional on USB) |

External (optional on USB) |

| High Speed Parallel and TTL Port (optional) |

Alarm outputs, trigger in/out control |

N/A |

| Analog Output |

Presence of echo in Gate, Thickness, Position of Echo flank in Gate, EchoStart + AUX |

N/A |

| A/D Sampling Frequency |

200 MHz |

50MHz |

| Probe connector |

Mini Lemo�� |

Molex - support up to 32-element probe. Probe and wedge data shall be inputted manually. |

| Number of Channel |

1 channel |

16 channels |

| Scan Type |

B-scan Thickness / RGB amplitude |

Linear / Sector |

| Focal Law quantity |

N/A |

max. 512 |

| Scan Angle Range |

N/A |

Linear: -45�� ~ +45��

Sector: -80�� ~ +80�� |

| Scan Setup |

N/A |

|

| Range |

0~29000mm for PRF 100Hz

(Steel longitudinal wave) |

0~29000mm for PRF 100Hz

(Steel longitudinal wave) |

| Material Velocity |

1~19999 m/s |

1~19999 m/s |

| Display Delay |

-25~29000mm

(Steel longitudinal wave) |

-25~29000mm

(Steel longitudinal wave) |

| Auto Transducer Calibration |

Zero offset and velocity |

Zero offset and velocity |

| Units |

mm, inch, ��s |

mm, inch, ��s |

| Refracted Angle |

Fixed settings of 0��, 30��, 45��, 60��, 70��; variable 10��~90�� in 0.1�� steps for calculations |

N/A |

| Test Modes: |

Pulse Echo, Dual, Through-Transmission, EMAT |

Pulse Echo, Through-Transmission |

| Probe Delay Range |

-10��s~4800��s with 5ns resolution |

-10��s~4800��s with 5ns resolution |

| Gate Monitors |

Four Gates: Floating gate, Interface gate, Measuring gate, Back-wall attenuator |

Four Gates: Floating gate, Interface gate, Measuring gate, Back-wall attenuator |

| Alarms |

Selectable threshold positive/negative or minimum depth modes |

Selectable threshold positive/negative or minimum depth modes |

| Cursors |

N/A |

Radius, Angle |

|

|

|

- Aerospace - composite testing

- Steel production - large castings, hot and cold rolled steel

- Engineering - welds and joints

- Railway - track junctions in manganese steel

- Energy - austenitic welds, drive shafts etc.

- Pipe inspection

- Crack detection and sizing

|

|

|

|

|